In any warehouse or distribution center, loading docks are the heartbeat of the operation. And at the center of that dock activity is the dock leveler. It may not look like much, but this piece of equipment plays a massive role in keeping the supply chain humming. A well-functioning dock leveler bridges the gap between trucks and your building, helping goods flow in and out smoothly. But when one breaks down, everything grinds to a halt—and the cost of that downtime can be huge.

Let’s dive into why dock levelers matter so much and what happens when they fail to do their job.

Why Dock Levelers Are Crucial for Supply Chains

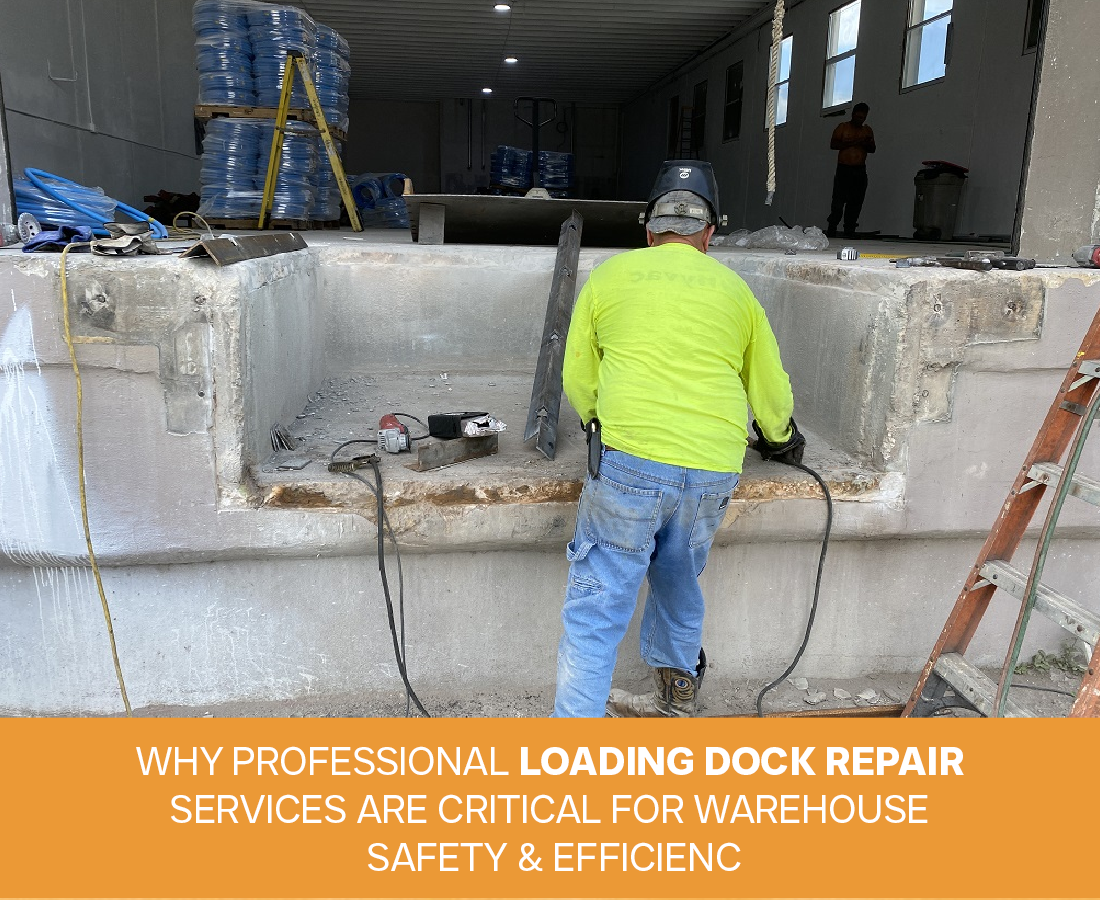

Dock levelers aren’t just metal plates. They’re custom-engineered to create a safe, level path between the truck bed and the dock. This helps forklifts and pallet jacks move quickly without damaging goods or risking worker injuries.

In modern logistics, speed is everything. Delays at the dock ripple through the rest of the supply chain—orders get backed up, delivery windows are missed, and efficiency takes a nosedive. That’s why reliable supply chain dock solutions always include proper leveler installation, inspection, and upkeep.

The Real Cost of a Failing Dock Leveler

A faulty dock leveler doesn’t just slow things down—it can stop operations altogether. Trucks might have to wait to be unloaded or re-routed, employees may be forced to use unsafe workarounds, and the chance of accidents skyrockets.

What’s more, the longer you ignore the issue, the worse (and more expensive) it gets. Neglected repairs can lead to major structural damage that may require full dock leveler replacement. That’s a cost no business wants to take on suddenly.

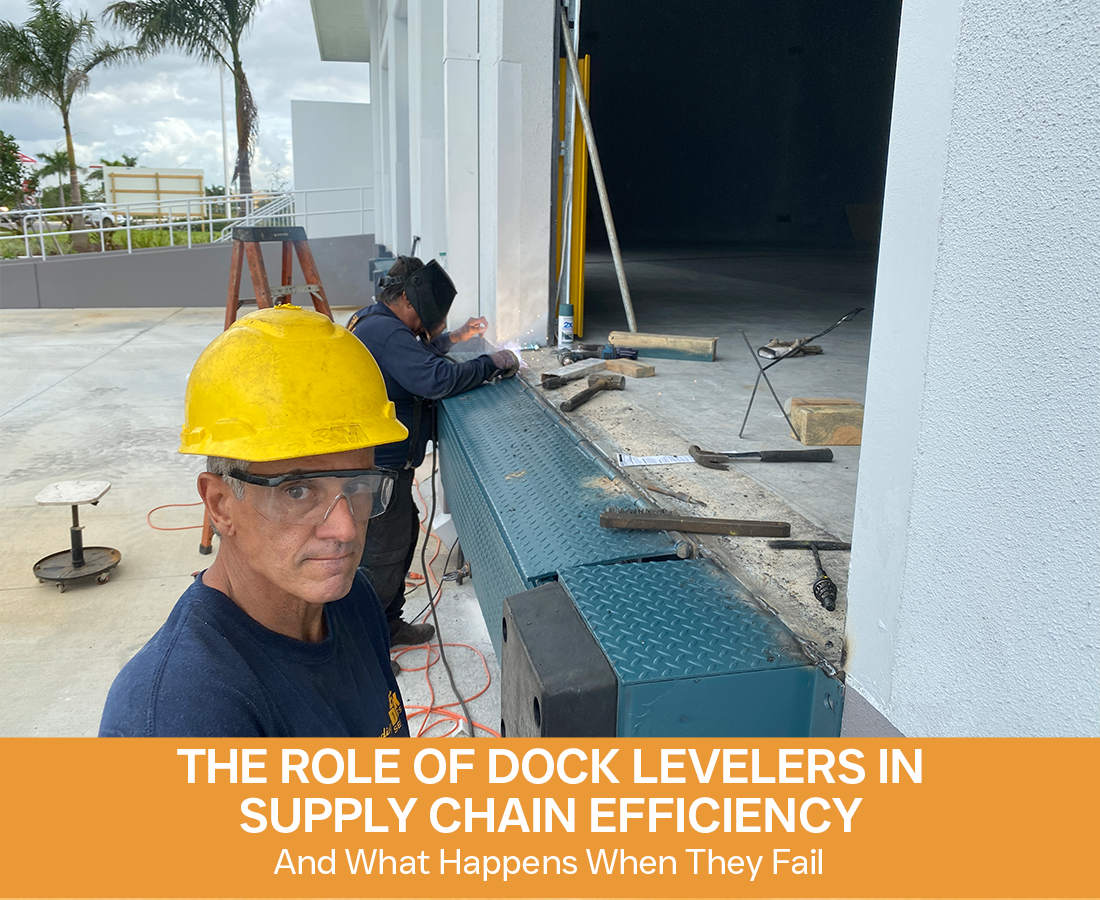

That’s where dock leveler repair services from BXC Dock Services come in. Our technicians can identify issues before they snowball and offer quick, on-site solutions to keep things moving.

Common Dock Leveler Issues to Watch For

Dock levelers work hard and take a beating. Over time, even the best equipment will show signs of wear. Here are a few common problems we see:

- Slow or unresponsive hydraulics

- Cracked welds or warped plates

- Uneven platform motion

- Air leaks in pneumatic systems

- Damaged lip extensions

- Electrical control problems

These might seem minor at first. But if left untreated, they can escalate fast. Regular dock leveler maintenance can help you avoid surprises and costly downtime.

Fast, Reliable Solutions from BXC Dock Services

At BXC Dock Services, a division of BargainXchange Inc., we specialize in all things dock-related. Whether you need emergency service, a new install, or a routine check-up, our team has your back. Our dock leveler installation experts make sure your equipment is properly fitted and code-compliant from day one.

If something goes wrong, we show up fast—with the right tools and parts on hand—to deliver top-tier dock leveler repair. We also offer planned maintenance programs to keep everything running smoothly long-term.

And because we know how much downtime costs, we aim to fix most issues on the first visit.

FAQs

Q1: How do I know if my dock leveler needs repair or replacement?

If it moves slowly, gets stuck, or shows visible damage, it likely needs repair. Repeated issues may indicate it’s time for a replacement.

Q2: How often should dock levelers be serviced?

At least twice a year for high-use docks, but quarterly inspections are best for busy warehouses.

Q3: Do you work on all types of dock levelers?

Yes. We service hydraulic, mechanical, and air-powered models from all major manufacturers.

Keep Your Supply Chain on Track

Your dock leveler isn’t just equipment—it’s a key part of your logistics team. And just like your crew, it needs care and attention to stay sharp. Investing in dock leveler maintenance and timely repairs helps avoid the kind of disruptions that hurt your bottom line.

At BXC Dock Services, we understand how critical these systems are to your day-to-day. Our licensed techs are ready to keep your docks safe, fast, and reliable—so your business never skips a beat.

Call us today at (786) 554-8077 to schedule a service or get a free estimate. Ask about our 10% discount for new customers and learn how we can extend the life of your equipment with expert, affordable dock leveler repair services.