Hydraulic scissor lift tables

BXC Dock Services offers dependable and ergonomic hydraulic scissor lift tables designed for a wide range of material-handling needs. These systems are ideal for jobs requiring vertical mobility and are commonly used as lifting aids in warehouses, loading areas, and production lines. They help bridge architectural gaps, enhance workflow, and improve worker safety and comfort.

Our lift tables are engineered to improve ergonomics and reduce physical strain on workers by adjusting work height to a comfortable level. Each hydraulic lift we provide is custom-built for industrial use, offering safe, long-lasting performance. Models can support up to 10,000 kg and are available in smooth or teardrop finishes. For lift heights exceeding 3 meters, we recommend using a forklift during operation.

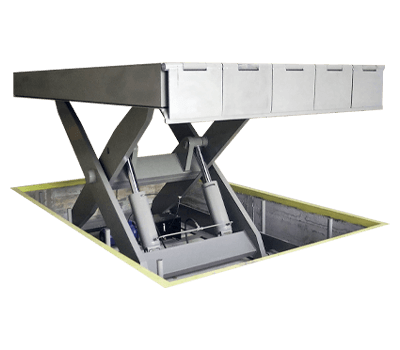

Single scissor lift table

This model is ideal for lifting and positioning goods between different levels. With access from all sides, it can support loads of up to 10,000 kg and span up to 5 meters in length. It meets the UNE EN-1570 safety guidelines and features a low folded profile. Capable of lifting to 0.6 times its length, it’s both functional and efficient. Features include:

1. Industrial-grade hydraulic platform.

2. Built for long-term operational use.

3. Fully compliant with global safety norms.

Double scissor lift table

Designed for applications that require added height, our double scissor model holds up to 5,000 kg and can extend up to 4 meters. It adheres to UNE EN-1570 standards and offers a lift range of 1.2 times its length. The folded height is moderate, making it compatible with many facility setups.

1. Reinforced hydraulic platform for added safety.

2. Handles mid to heavy load capacities.

3. Comes with safety profiles on all sides.

Multiple scissor lift table

This variant is built for scenarios where higher lift capacity is essential. With configurations that include three or four stacked scissors, this model can achieve significantly higher elevations than single or double designs. It includes a base, lift mechanism, and platform.

We tailor every table to the client’s needs and can include features that improve safety, performance, and versatility. These include:

With canvas metallic bellows

The bellows enclose the table’s perimeter to guard against moisture and debris. In exterior applications, they help resist outdoor wear and tear, keeping equipment functional longer.

With manual or hydraulic lip

These lips bridge the lift table and the truck or dock edge. They can be controlled either manually or through a hydraulic system for smoother transitions during loading.

With loading dock

When integrated into a dock setup, the lift includes a lip (manual or hydraulic) for load transfer. Optional curtains can be added to block smoke and airborne particles from entering the facility.

With railings

We recommend railings for applications that require additional worker or load safety. These include side guards measuring 1100mm in height with 120mm kickplates for added protection.

Scissor tables for special applications

Machines with double vertical or horizontal scissors

These are designed for demanding lifting scenarios. With double scissors arranged vertically or horizontally, these models offer increased strength and reach. Powered by a single hydraulic unit, they’re ideal for extra-large or irregular loads.

1. Supports greater weight and reach.

2. Configurable for unique operational tasks.

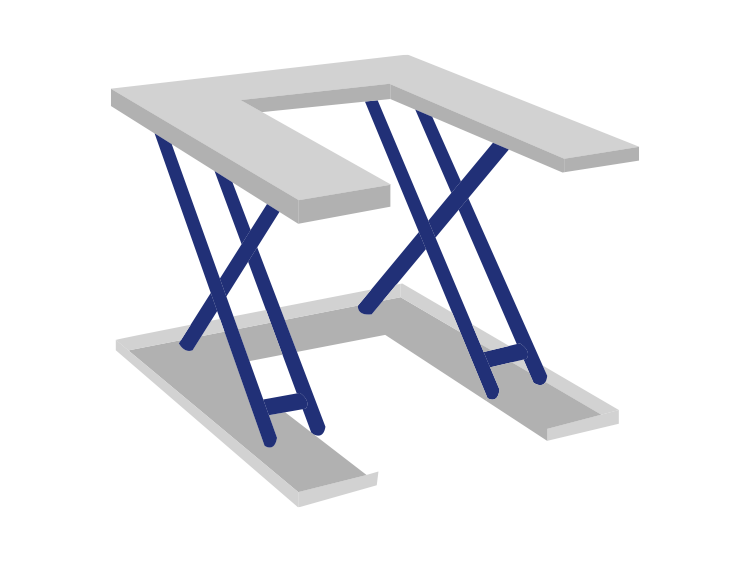

Extra flat lift tables

Extra flat models are ideal when pit installation isn’t possible. Their low folded design allows them to sit flush with the ground. Tops can be E, U, or rectangular, depending on your layout.

Each unit includes:

1. Chassis: base component resting on the floor, housing hydraulic parts.

2. Extendable Structure: connects the chassis to the platform and provides lift.

3. Platform: the upper surface for goods or personnel, supported by the frame.